Menu

Process Reactors &

Pressure Vessels

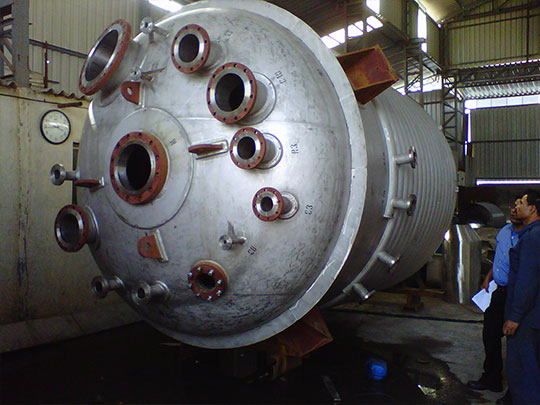

At the heart of every industrial process systems across industries is a Process Reactor. An industrial process reactor is an important chemical equipment that facilitates a wide range of processes such as optimal mixing, flow distribution, heat transfer, mass transfer, diffusion, etc. to deliver high-quality product.

Process reactor is a generic term used for equipment that carry out a variety of processes including hydrogenation, oxidation, ethoxylation, bio-fermentation, neutralization, bromination, chlorination, etc. and processes that require critical equipment to create a process conducive environment for the reaction to occur at desired levels. Depending on the nature of reaction, a reactor may serve as a holding tank, heat exchanger, mixing tank or a mass transfer device. Chemical reaction generates desired product and by-products that can be used in downstream processes.

ACME REACTORS

ACME understand that a successful commercial unit is an economical balance of all the above mentioned factors, and designs reactors after considering every minute detail of the process requirement, also including: yield, purity, pollution, temperature, pH, oxygen, operating costs, downtimes and nutrient concentration.

With proven expertise for adiabatic reactors, batch reactors, semi-batch reactors, continuous flow reactors, and more, ACME products have performed flawlessly delivering higher rate of desired output. ACME uses computational fluid dynamics (CFD) as a simulation tool for the development, design, and optimization of processes in chemical and biochemical engineering. With the use of latest and advanced software, ACME has gained its expertise in designing the reactors as per ASME Sec VIII Div. I & PED 2014/68/EU.

Ranging from 0.01 m3 to 90 m3, ACME has manufactured cGMP compliant multiple capacity reactors and pressure vessels in various raw materials grades such as:

- Austenitic Steels - SS 304/304L, SS 316/316L, SS 321, SS 317/317L, SS 904L

- Duplex Steels - Duplex 2205, Duplex 2209,

- Carbon & Mild Steels - SA 516 Gr. 70, IS 2062,

- Exotic Steels such as - Hastelloy C-276, Hastelloy C-22, Titanium Gr. 2, alloy 20, Inconel, etc.

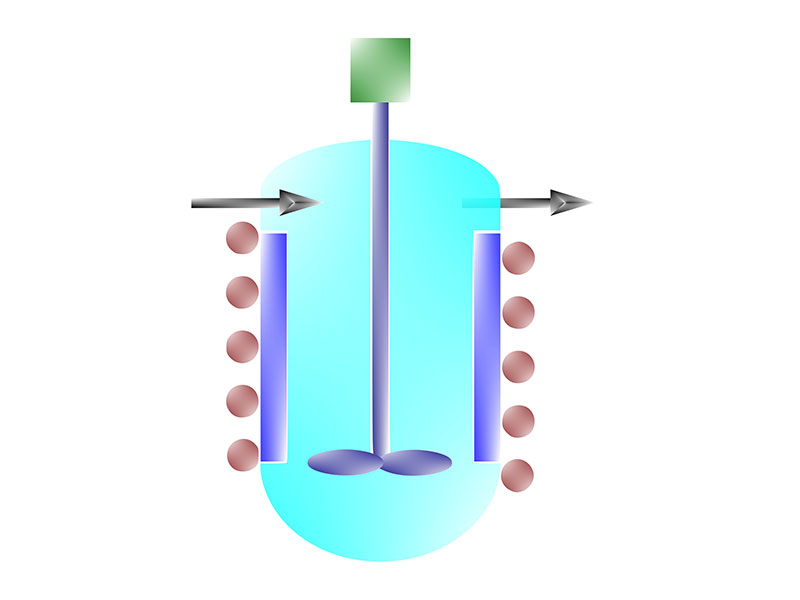

STRUCTURE OF A TYPICAL PROCESS REACTOR

Reactor with process-specific MOC

Agitators and Impellers

Process Parameterization

Process Inducing inlet

Outlet

FEATURES & BENEFITS

ASME SECTION 8, DIV 1 code used for reactor design and manufacturing

- Thorough understanding of the process requirements

- Optimal and robust process design with low power consumption

- Authentic material of constriction

- Great welding, excellent surface finishing (WPS/PQR qualified welders)

- Appropriate heat treatment assures stress relief and longevity

- Crack resistant material

- Leakage-proof, inherently safe

- Easy to clean

- Very low maintenance cost

- High quality standards to ensure easy functioning under various pressures

INDUSTRIES

- Chemical Process Industry

- Petrochemical Industry

- Oil and gas refineries

- Waste and Water treatment

- Paper and pulp

- Medical & Biopharmaceuticals

- Fertilizers

- Food

- Beverages

- Vegetable Oil

- Dyes

- Hydrogenation

- Polymer industry

- Paints

- Mineral processing

APPLICATIONS

Catering to multiple process industries, ACME has developed its reactors to function efficiently in high pressure & high temperature applications, high corrosion resistance applications and Cryogenic applications.

- Fermentation of beverage products

- Waste water treatment

- Polymerization

- Brewing

- Oil cracking

- Gasoline production petrochemical products

- Fertilizer manufacturing

- Oxidation process

- Hydrogenation process

- Nitration process

- Synthesis of chemical intermediates

APPLICATIONS

Catering to multiple process industries, ACME has developed its reactors to function efficiently in high pressure & high temperature applications, high corrosion resistance applications and Cryogenic applications.

- Fermentation of beverage products

- Waste water treatment

- Polymerization

- Brewing

- Oil cracking

- Gasoline production petrochemical products

- Fertilizer manufacturing

- Oxidation process

- Hydrogenation process

- Nitration process

- Synthesis of chemical intermediates

Through ACME’s engineering excellence SAVE ENERGY IMPROVE EFFICIENCY ACHIEVE SUSTAINABILITY

DOWNLOAD BROCHURE

CONNECT WITH US

SEND AN ENQUIRY

SAVE ENERGY | IMPROVE EFFICIENCY | ACHIEVE SUSTAINABILITY

Through ACME’s Hydrogenation Engineering

Our Clients

They Believe In Us