GAS INDUCTION VS HYDROFOIL

GAS-INDUCTION TYPE

HYDROFOIL

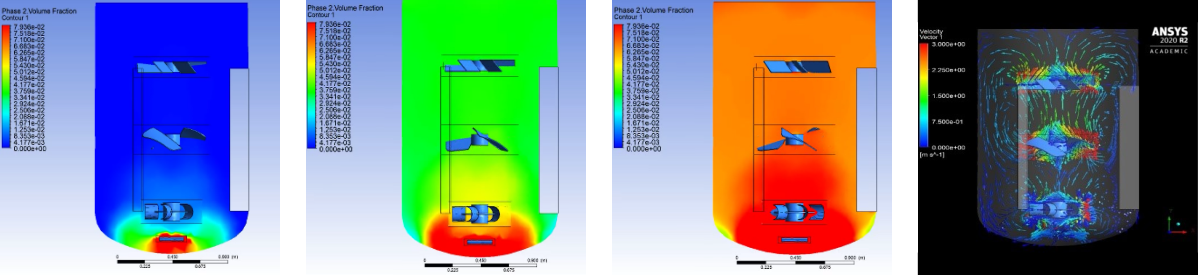

Gas is re-induced through pipe and pushed away from impeller mixing zone. So Gas moves away from turbulence | Gas is induced below the impeller in max turbulence zone of impeller so gas bubble size is reduced |

Impeller small in size so solid suspension is not uniform throughout liquid mass | Impeller to tank Ø ratio is 0.3-0.5 so solid suspension is uniform as it is axial flow down pumping impeller |

Suction of gas in vapour space is from shaft and sparged from tip so gas velocity cannot be controlled | Velocity is controlled by sparger ring and impeller sees conducive velocity |

Gas is sparged at tip of impeller so gas is pushed away from mixing/turbulence zone of impeller at high velocity | Gas is sparged in the max turbulence zone of impeller so gas dispersion occurs throughout tank |

Continuous loop formed gas sucked and goes back in vapour space without reacting so batch time increased | Top impeller continuously changes upper liquid layer so new mass is in contact with vapour space gas every mili- second and reaction rate enhanced |

Impeller being smaller cannot hold large volume of gas in liquid mass | Impeller big and solidity high so this pressure type impeller ensures huge gas hold up in liquid mass |

Generally single impeller so re-entrainment of gas is difficult | Multiple impeller so re-entrainment of gas is very much a part of system |

Batch time observed to be higher | Batch time is 50-60 % lesser than gas-induction type impeller at same or lesser power consumption |

Combination of gas-induction with hydrofoil will help making system more efficient | Gas-induction will enhance the performance of this system |