Menu

Agitators

The Leading manufacturer in India.

Industries across the globe have been extremely vigilant about minimizing operational costs, improving efficiencies, implementing strategies to reduce energy consumption and maximizing productivity. Post 2020, this has become even more evident across different industrial domains, but particularly more prominent in the process industries such as food, pharmaceuticals, chemicals, etc.

These enterprises are strongly pursuing methods to substantially optimize mixing processes, lower the energy consumption, flow maximization and employing futuristic technology. They don’t need a product. They need a partner, who can help achieve the above targets by collaboratively identifying solutions for their specific process requirements.

ACME Agitators

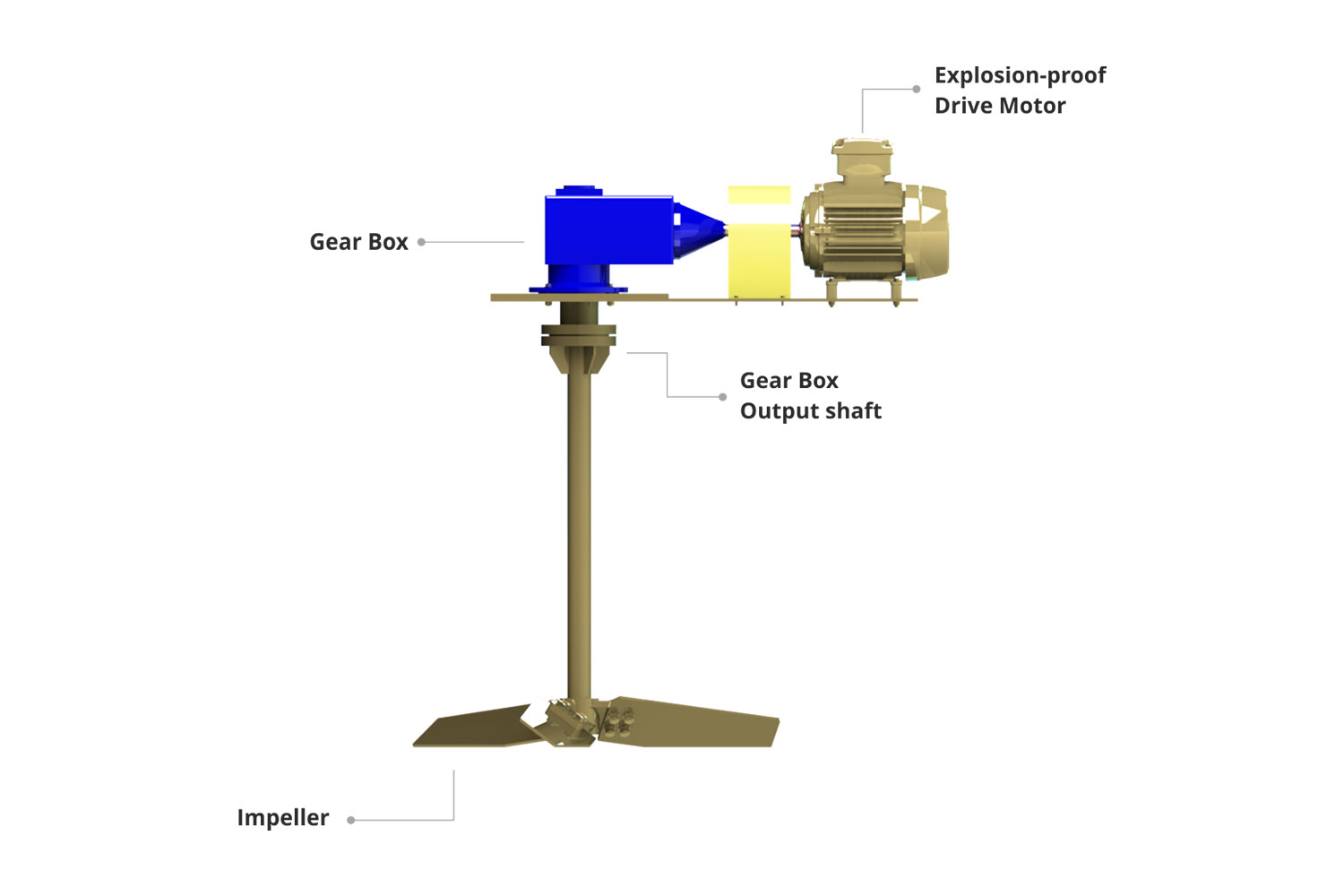

ACME’s chemical engineering experts design, build and help you implement the agitators customized for your processes.

ACME agitators ensure efficient process of various heterogenous chemicals, whether it’s for heat transfer, mass transfer, triggering effective chemical reaction, thorough dispersion, retaining uniformity, extraction, etc.

Recognized by several industry giants.

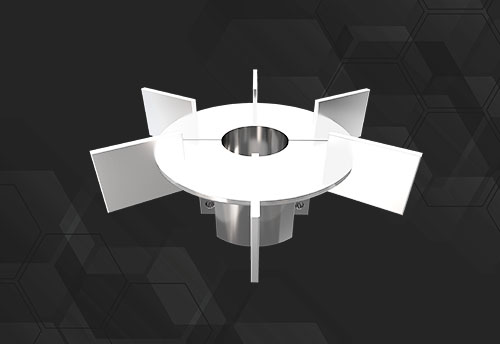

ACME’s expertise in designing and manufacturing a wide range of highly efficient impellers that are process-specific

ACME agitators ensure efficient process of various heterogenous chemicals, whether it’s for heat transfer, mass transfer, triggering effective chemical reaction, thorough dispersion, retaining uniformity, extraction, etc. ACME’s chemical engineering experts design, build and help you implement the agitators customized for your processes.

We design and manufacture a wide range of agitators that lower energy consumption, increase yield and reduce batch times. The payback periods on power alone are as low as 6 to 8 months. ACME agitators are designed and manufactured built with better performance, superior quality and longevity.

Understanding the overall process, the elements involved in the mixing process, their homogenization, appropriate forces at action, etc. are important aspects while building the right agitator. The efficiency of these also depend on the choice of impellers.

Types of Acme Impellers

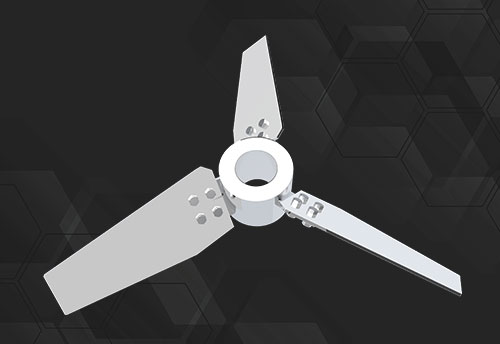

AA-302/AA-303 – Hydrofoil

Use of this impeller type facilitates huge saving of motor power as most of it is converted into flow bearing axial velocity vectors. This is utilized for various flow-based application having fluids with viscosity less than 4,000 cPs. The key feature of this impeller type is to save huge motor power, lowered batch time and improved process results.

AA-304 – High Viscosity Hydrofoil

This impeller type is developed for applications having viscosity up to 160,000 cPs. This facilitates better flow in high viscosity. This is also used for a mix of shear and flow type application, pressure flow pattern.

AA-405 – Gas-Liquid-Solid application

This impeller type is used for better gas hold up, dispersion and uniform solid suspension. At same power as that of primitive impellers 15% more mass transfer / yield is delivered. This hydrofoil can be used in down pumping as well as up pumping.

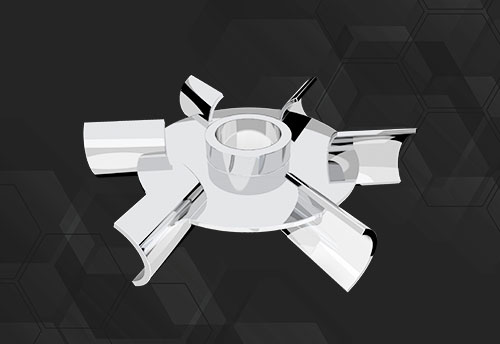

CBT-601 – Shear-Gas

It is used for gas-liquid application where shear is not detrimental to the process. It’s a reformed version of Rushton Turbine, as for lower powers too it gives the same performance. This impeller performs much better when it is used in as a combination with AA-405 or AA-303.

Pitched Blade Turbine (PBT)

This is used in high as well as low viscosity applications. It has both axial as well as radial velocity vectors. It helps in applications where flow and shear are required. Largely replaced by AA-302 because of high power efficiency.

Cowl’s Disc – Saw Tooth

This is implemented for high shear applications. It helps in breaking of solids inside liquid mass, dispersion applications. It is mostly designed as a direct driven (motor RPM) with high tip speeds for cutting action.

Anchor

This impeller is generally used for high viscosity applications. It is also used for those applications where material sticks to the walls of vessel and heat transfer on external jacket is hampered. Spiral helix performs better than anchor. PTFE / Teflon scrappers are attached to the anchor for applications where scraping action is required, e.g., in paints, adhesive, pesticides, crystallizers and more applications.

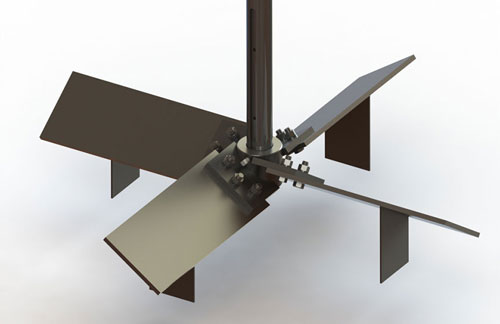

Marine Propeller

This impeller has been specifically designed for robust performance. Though expensive due to high quantity of MOC, ACME Marine Propellers are built with reasonable cost without compromising on the quality of the construction materials. The axial flow impellers adapted from rigs propel impellers. This performs well in highly viscous applications too.

Double Twist DB – 1

This is a specially designed impeller for bottom entry agitators. Widely used in brewery plants, it generates multiple direction flow which ensures no settling at the bottom.

Spiral Helix

These are single flight and double flight impellers with screw arrangement. Used for crystallization processes where material is either high viscous or solid, formed due to condensation crystallization, sticks to the walls / cooling surface of the vessel.

CBT – 602 – Shear Gas-Liquid –

This is employed for gas-liquid application where shear is not detrimental to the process. This is reformed version of CBT-601, it has ellipsoidal design. It gives a better performance at lower input power.

FBT-101 – Rushton

These are Primitive impellers used for shear applications. They are also implemented in gas-liquid applications where shear is not detrimental to the process.

Features

- Wide speed range

- Enhanced process control

- Versatility

- Simple design

- High efficiency

Benefits

- More flow with less power

- Wide range of process-specific impellers

- Process control experts ensure smoother operation

- Low operational cost leading to energy saving

- Reduced batch cycle

- Optimal Maintenance

- Longevity

Industries

- Pharmaceutical

- Chemical

- Food processing

- Cosmetic

- Paper & Pulp

- Waste water

- Petrochemicals

Our Clients

They Believe In Us