Menu

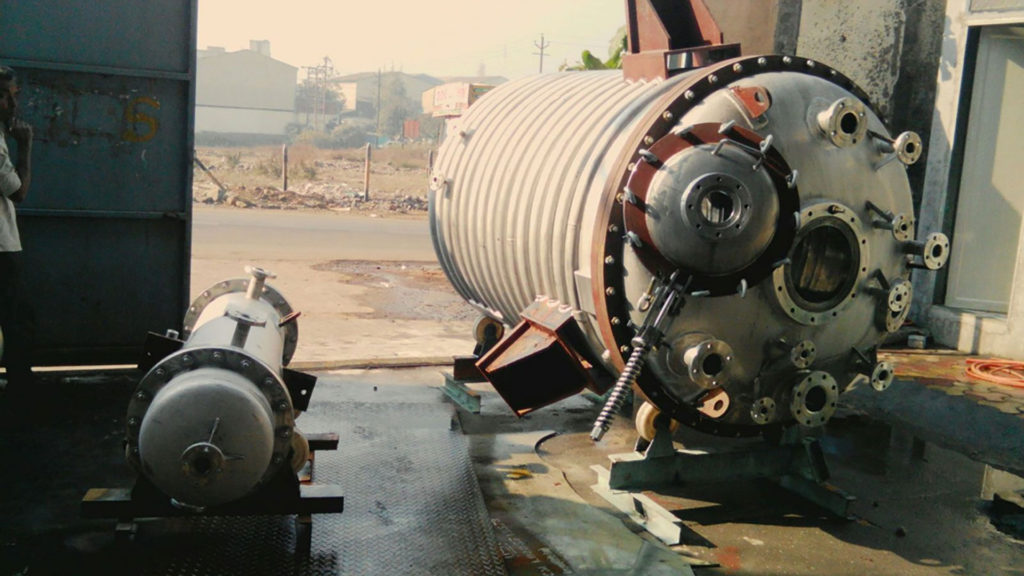

AGITATORS

The leading agitator manufactures in India

Industries across the globe have been extremely vigilant about minimizing operational costs, improving efficiencies, implementing strategies to reduce energy consumption and maximizing productivity. Post 2020, this has become even more evident across different industrial domains, but particularly more prominent in the process industries such as food, pharmaceuticals, chemicals, etc.

These enterprises are strongly pursuing methods to substantially optimize mixing processes, lower the energy consumption, flow maximization and employing futuristic technology. They don’t need a product. They need a partner, who can help achieve the above targets by collaboratively identifying solutions for their specific process requirements.

What Others Say?

The performance of the agitator supplied by Team ACME for the lubricants blending is highly satisfactory and I really appreciate the efforts from team ACME for the same.

We here by confirm that we have been buying Agitators since Year 2010 till date; from Acme Process Systems, Plot No. 311, Sector No.7, PCNDTA, M.I.D.C., Bhosari, Pune - 411 026. The performance of all Agitators supplied is satisfactory.

We have observed a 60% batch time reduction in our hydrogenator autoclave for no additional power input.

We are satisfied with the performance and benefits of the agitator with hydrofoil impeller technology supplied by Acme Process Systems.

Previous

Next

TYPES OF ACME IMPELLERS

AA-302/AA-303 – HYDROFOIL

Use of this impeller type facilitates huge saving of motor power as most of it is converted into flow bearing axial velocity vectors. This is utilized for various flow-based application having fluids with viscosity less than 4,000 cPs. The key feature of this impeller type is to save huge motor power, lowered batch time and improved process results.

AA-304 – HIGH VISCOSITY HYDROFOIL

This impeller type is developed for applications having viscosity up to 160,000 cPs. This facilitates better flow in high viscosity. This is also used for a mix of shear and flow type application, pressure flow pattern.

AA-405 – GAS-LIQUID-SOLID APPLICATION

This impeller type is used for better gas hold up, dispersion and uniform solid suspension. At same power as that of primitive impellers 15% more mass transfer / yield is delivered. This hydrofoil can be used in down pumping as well as up pumping.